Products

“The Light Amplification by the Stimulated Emission of Radiation!”

Every object in the universe is made up of atoms. These atoms are constantly in motion; vibrating, moving and rotating. Atoms can be in different states of excitation; either ground state or excited level.In order for an atom (electron) to reach an excited level some type of energy must be applied via heat, light or electricity.

Once an electron moves to a higher-state, it wants to return to its original state. When it does, it releases its energy as a photon a particle of light.

These photons of light are what we use in lasers. Although there are many types of lasers, they all have certain essential features. Either a rod or a gas tube is excited by light or electricity (flash lamp, diodes or RF frequency) to release photons of light.

Laser marking is a generic term used to refer to several processes:

The above processes are selected on the basis of the material used and the quality requirements of the application.

“Deep marks in all materials for performance or 2D, 2½ D and 3D effects”

During Laser Engraving, the target material is essentially vaporized by the laser beam within a few nano-seconds. This is achieved by the higher intensity of the laser beam. Through the interaction of the melted base material with atmospheric oxygen, oxides are often formed. Due to the color of oxides, it makes the engraving stand out more clearly. The laser engraving technique is typically the fastest way of processing material.

“Superficial, but permanent laser marks with some material removal”

During the ablation process, a top (covering) layer is evaporated by laser beam. When ablating the top layer of coated metals, the laser beam does not interact with the base material, but only with the coating layer. Very thin layers such as color and/or anodizing layers are especially suited for laser engraving. High contrasts can be achieved with a small amount of laser power since these layers absorb laser radiation extremely well. Examples are: anodized aluminum, day & night design or laser marking foils. With a "day & night" design, e.g. for car dashboards, can be achieved by removing one color layer.

“Black surface marks on metals created by bringing carbon to the surface”

A contrasting mark can be created using an annealing effect on metallic materials. The laser beam heats up the metal below its melting point, creating structural changes in the surface. The color of the mark is determined by the maximum temperature attained in the metal, the properties of the metal, and the parameters selected on the laser. The annealing technique has a unique characteristic in that it produces a contrasting mark without disrupting the surface finish of the metal.

During this process, the laser radiation penetrates the material (plastic, stainless steel) and is absorbed by the color pigments. As a result, the pigments are chemically modified, resulting in a color change in the material. Since the laser radiation penetrates into the plastic, the surface remains almost undamaged. The color change achieved depends on both the pigment and the basic material used.

| Marking Process | Speed | Permanence | Image Flexibility |

| Laser Marking | Good | Excellent | Excellent |

| Chemical Etch | Good | Fair | Poor |

| Photo Etch | Good | Fair | Poor |

| Ink-Jet | Good | Poor | Good |

| Mechanical Stamping | Good | Good | Poor |

| Nameplates* | NA | Moderate | Poor |

| Casting / Molding | Good | Good | Poor |

| Pneumatic Pin | Moderate | Good | Moderate |

| Vibratory Pencil | Poor | Good | Good |

| CO2 Mask Marker | Good | Moderate | Poor |

Lasers are rated at different classifications based on the level of exposure.

| CLASS I | Class I lasers are low powered devices that are considered safe from all potential hazards. Some examples of Class I laser usage are: laser printers, CD players, etc. No individual, regardless of exposure conditions to the eyes or skin, would be expected to be injured by a Class I laser. |

| CLASS II | Class II lasers are low power (< 1mW), visible light lasers that could possibly cause damage to a person's eyes. Some examples of Class II laser use are: classroom demonstrations, laser pointers, aiming devices and range finding equipment. If class II laser beams are directly viewed for long periods of time (i.e. > 15 minutes) damage to the eyes could result. Avoid looking into a Class II laser beam or pointing a Class II laser beam into another person's eyes. Avoid viewing Class II laser beams with telescopic devices. Realize that the bright light of a Class II laser beam into your eyes will cause a normal reaction to look away or close your eyes. This response is expected to protect you from Class II laser damage to the eyes. |

| CLASS III | Class IIIa lasers are continuous wave, intermediate power (1-5 mW) devices. Some examples of Class IIIa laser uses are the same as Class II lasers with the most popular uses being laser pointers and laser scanners. Direct viewing of the Class IIIa laser beam could be hazardous to the eyes. Do not view the Class IIIa laser beam directly. Do not point a Class IIIa laser beam into another person’s eye. Do not view a Class IIIa laser beam with telescopic devices; this amplifies the problem. |

| CLASS III B | Class IIIb lasers are intermediate power (c.w. 5-500 mW or pulsed 10 J/cm²) devices. Some examples of Class IIIb laser uses are spectrometry, stereolithography, and entertainment light shows. Direct viewing of the Class IIIb laser beam is hazardous to the eye and diffuse reflections of the beam can also be hazardous to the eye. Do not view the Class IIIb laser beam directly. Do not view a Class IIIb laser beam with telescopic devices; this amplifies the problem. Whenever occupying a laser controlled area, wear the proper eye protection. |

| CLASS IV | Class IV lasers are high power (c.w. > 500mw or pulsed > 10J/cm²) devices. Some examples of Class IV laser use are surgery, research, drilling, cutting, welding, marking and micromachining. The direct beam and diffuse reflections from Class IV lasers are hazardous to the eyes and skin. Class IV laser devices can also be a fire hazard depending on the reaction of the target when struck. Much greater controls are required to ensure the safe operation of this class of laser devices. Whenever occupying a laser controlled area, wear the proper eye protection. Most laser eye injuries occur from reflected beams of class IV laser light, so keep all reflective materials away from the beam. Do not place your hand or any other body part into the class IV laser beam. The pain and smell of burned flesh will let you know if this happens. Realize the dangers involved in the use of Class IV lasers and please use common sense. |

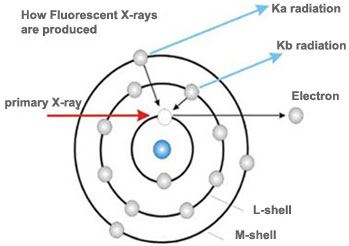

High energy photons emitted by an X-ray tube interact with matter. The high energy photon is absorbed by an electron of the atom. This electron is accelerated and forced to leave the atom. The so created hole in the structure of the electron shell is filled up by an electron of higher energy. The difference in energy between the leaving electrons position and the filling up electron may leave the atom as a photon of defined energy or as an electron. In the case of a leaving photon this process is called X-ray fluorescence and the energy of the leaving photon is characteristic for this atom and therefore for the element. The electron shells of an atom are called K-, L-, M-shell. Filling up a hole in the K–shell creates K–radiation (Ká if the filling up electron has is origin in the L–shell; Ká if the filling up electron has is origin in the M–shell). Filling up a hole in the L–shell creates L–radiation and so on. Only K and L radiation is on interest because the energy of K and L radiation is in the region which can be detected with standard detectors.

Contact us +91 7575806266 Email : sales@vesindia.org, bhavesh.pethani@gmail.com

| Home | Business Profile | Products | Blog | News | SiteMap | Contact Us | About Us